export Tearing Resistance Testing|tear resistance calculation : manufacturing The tensile strength of a material is the maximum mechanical tension it can withstand before it cracks. It is given in N/mm² or MPa. The tear resistance of a material, also called tensile strength at break, is the mechanical tensile stress .

Homegrown Big Tits. 438.3K views. 12:46. PREMIUM - ONLYPERVS - AMATEUR GRANNY: 80 YEARS OLD REDHEAD FOOT FETISH AND CUM SWALLOWING .

{plog:ftitle_list}

Tiger Style. Tiger is a style that combines a good balance of offensive, defensive, and evasive maneuvers especially designed for one-on-one fights. While using this style, you .

tensile strength vs tear test

ASTM D1922: This standard measures the propagation tear resistance of plastic films and thin sheeting. ASTM D689: This standard applies to measuring tearing resistance of paper. ISO 1974: This standard details the tearing resistance test for paper and board using the internal tear .A tearing resistance tester is specifically designed to measure the force required to propagate a tear in a sample material. This measurement is crucial for determining the durability and .

tear testing methods

Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under .

Tear resistance testing can be found in plastic film, paper and textile industries. Tear resistance is the measurement of a sample’s ability to resist tearing. Tear resistance can be impacted .

One way to measure tear resistance is through the Pendulum Method or Elmendorf Tear Test, as defined by ASTM D1922. The Elmendorf Tear Test is a simple and reliable way to measure the force required to propagate a slit in a plastic film a fixed distance to the edge of the test sample. The test is performed using a pendulum impact tester, which .

The tensile strength of a material is the maximum mechanical tension it can withstand before it cracks. It is given in N/mm² or MPa. The tear resistance of a material, also called tensile strength at break, is the mechanical tensile stress .

Testing System. This standard requires a test frame moving at a constant rate of extension. As with most textiles testing, data rate is an important consideration, and to consistently and accurately measure the tear strength of your material .ISO 6383-1:2015(E) 8 Number of test specimens 8.1 A minimum of five test specimens shall be tested in each of the required directions of testing. 8.2 Specimens which show a tear out of line to the extent that the tear reaches one of the edges of the test specimen shall be discarded and further specimens tested (see 11.3). 9 Speed of testing

This Complete Guide of the Elmendorf Tear Testing explores tear resistance testing dimensions, application areas, standards, methodologies, troubleshooting, and the future landscape of tear analysis. Key takeaways and practical insights empower informed decisions in material science. Application of Elmendorf Tear Testing in Industry

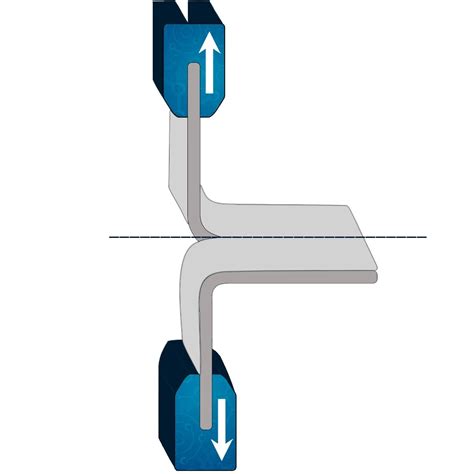

tear resistance vs strength

Tear resistance can be impacted considerably by the speed of the test, e.g. test speed used in generate the tear. Tear propagation resistance for the purpose of acceptance testing is common with materials such as paper and rubber. Tear resistance in textiles involves the load required to propagate a single “rip-tongue” type of tear (tear .Originally introduced in 1964, ASTM D2261 was most recently updated in 2013 and specifies the method for tear testing of fabrics by the tongue (single rip) procedure to measure the tearing strength of the fabric. This test method applies to most textile fabrics, including those that are treated and untreated, woven, knitted, or unwoven.ISO 1974:2012 specifies a method for determining the (out-of-plane) tearing resistance of paper. It can also be used for boards having a low grammage if the tearing resistance is within the range of the instrument. ISO 1974:2012 does not apply to corrugated fibreboard, but it may be applied to the components of such boards.This ensures better accuracy and reliability in testing tear resistance. This layout minimizes outside factors on the pendulum’s motion. It lowers the chance of errors in the test results. . Automatic data storage and analysis: the Tear Resistance Tester can automatically save, export, and analyze the test data to help manufacturers track .

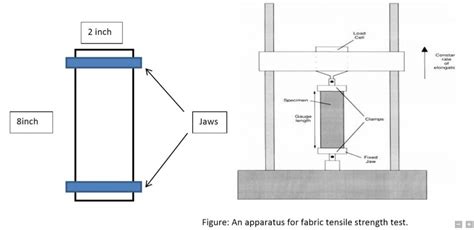

The size of the specimen and related fixtures requires the use of a dual column system, while the tensile and tear resistance tests can be performed on either a dual column or a single column system, such as Instron's 68SC-5 model. A 5kN or 10kN (1125 or 2250 lbf) system is the most common, capable of applying the vast majority of compressive . Fabric tear resistance is crucial for safety, product durability, and customer satisfaction. The Elmendorf test is a standardized method widely used across industries. It helps quantitatively . testing and data analysis were completed March 26, 2018 with yield data being analyzed April 3 The scope of , 2018. work was limited to conducting tear, tensile, and puncture tests on the submitted samples and reporting the results. CONCLUSIONS . Tear Testing Conclusions . Sample Average Tear Resistance Force, lbf Average Resistance

Tear resistance is the measurement of a sample’s ability to resist tearing. Tear resistance can be impacted considerably by the speed of the test, e.g. test speed used in generate the tear. Tear propagation resistance for the purpose of acceptance testing is common with materials such as paper and rubber.

Product Code: UEC-1008 A: Equipment Category: Physical Property Testing Equipment: Weight: Main Unit with Pendulum "B" - 22.500 Kg. Dimension “Main Unit with Single Pendulum”- 45.0 x 23.0 x 50.0 cm.

Reduction of tear resistance as a consequence of defects in soft biological tissues is relevant for a number of medical problems. . Polym. Test. 60, 117–123 (2017).Testing System. This standard requires a test frame moving at a constant rate of extension. As with most textiles testing, data rate is an important consideration, and to consistently and accurately measure the tear strength of your material .Three standard methods are available for determining tear resistance of plastic films: ASTM D-1004 details a method for determining tear resistance at low rates of loading; a test in ASTM D-1922 measures the force required to propagate a precut slit across a sheet specimen; and ASTM D-1038 gives a method for determining tear propagation .ISO 1974 was prepared by Technical Committee ISO/TC 6,Paper, board and pulps, Subcommittee SC 2, Test methods and quality specifications for paper and board. . This International Standard specifies a method for determining the (out-of-plane) tearing resistance of paper. It can also be used for boards having a low grammage if the tearing .

Testing with the ProTear is easy - simply secure the sample in the clamps, make an initial tear with the attached blade and release the pendulum. The tearing resistance of the material is measured via the transference of the potential energy stored in the raised pendulum to kinetic energy. A portion of this energy is absorbed during the tearing ofTearing Strength Tester. Tearing strength testing can be found in plastic film, paper and textile industries. It is used to describe how well a material can withstand the effects of tearing. Elmendorf tear is a common method that is used to test tear resistance.

The tearing strength tester is an appropriate tool to measure the tear resistance of various materials including textiles and fabric. Types of tear test: Tongue Test; Trapezoid; Elmendorf; Measurement of fabric tearing strength: Elmendorf tear tester: Sample Preparation: First we take specimen of 100 ×75 .ASTM D1004 Tear Resistance This test method covers the determination of the tear resistance of flexible plastic film and sheeting at very low rates of loading, 51 mm (2 in.)/min. and is designed to measure the force to initiate tearing. The specimen geometry of this test method produces a stress concentration in a small areaProduct Code: UEC-1008 C: Equipment Category: Physical Property Testing Equipment: Weight: Main Unit with Pendulum "B" - 19.00 Kg. Dimension: Main Unit with Single Pendulum - 43.0 x 32.5 x 61.5 cm.The mean force required to continue the tearing of an initial cut in a single sheet of paper is expressed as the internal tearing resistance. If the initial slit is made in the machine direction, the result is given as machine direction tearing resistance and similarly for the cross-machine direction (ISO 1974). Why measure tearing resistance?

custom general pin type moisture meter instructions

can be used to calculate the approximate tearing resistance of a single sheet. It is not suitable for single-ply tear testing; a separate method for single-ply tear will be available. 1.2 It is not suitable for determining the cross-directional tearing .

Well, the force needed to tear the material is measured, and it offers a reliable indication of its tearing resistance. This materials test is suitable for a wide range of fabric types that contain woven, knitted and then non-woven materials. It is frequently preferred for thicker and heavier fabrics that are used in applications such as .Purpose: This test method is used to determine the average force (grams) to propagate tearing through a plastic film in machine and/or transverse direction. Sample: We usually need about one (1) square foot of plastic film for each test direction. Price & Delivery: Contact us for a quote. Basic Description: An impact tester with a pendulum is used to measure the force (grams) .

tear resistance testing machine

tear resistance testing

tear resistance calculation

Resultado da 27 de ago. de 2023 · Para fazer um boquete perfeito, é importante entender o corpo masculino e suas zonas erógenas. O contato visual é muito .

export Tearing Resistance Testing|tear resistance calculation